Reefer units or refrigerated ‘vans’ are used more intensively in summer which makes winter the best time to give them a detailed check and repair any damage. This checklist is also useful for pre-trip inspections and if you are looking to buy a secondhand reefer.

The best way to do an inspection on a refrigerated trailer or truck body is to have a system so you don’t miss anything. Start at one corner and walk around it, then walk around it the other way, checking for wear and tear or damage.

Air lines and electrical connections

Where the air lines and electrical systems are connected is exposed to the elements. Check that there is no damage which might crimp the airlines. If the EBS (electronic brake system) is damaged, the brakes won’t work properly on the trailer, putting much more pressure on the brakes of the tractor unit.

Side and rear doors

Check them for cracks and that they close securely. If the doors don’t close, humid, warm air from outside will be sucked in and the chiller unit has to work extra hard. There should be no movement in the doors when they are closed.

Check doors when they are open, too – look for damage to the hinges and the inside lining.

Huck rail

Check the huck rail (the aluminium plate that runs along the side of the trailer holding the body to the chassis. Look for missing bolts and signs of deflection.

Cant rail

The cant rail is at the top of the trailer. Damage here can cause water to enter into the body, causing the insulating foam to break down. This is an expensive repair.

Landing legs

Look for missing bolts or anything that’s bent in this area as it could be an indication that the trailer has been dropped on its legs. While you’re there, check the chassis doesn’t look bent.

Floor

Open the rear doors and look down the full length of the floor for straightness. Bumps where the legs are mounted point to the trailer being dropped – investigate further. Check the condition of the floor by walking the full length of the trailer, looking for cracks in the floor’s coating, soft spots and damage where the floor joins the walls.

Walls and ceiling

Check for dents, cuts and other damage that could expose the foam and areas of rust. Check for mould (the trailer should be aired frequently to prevent this from happening).

Battery

If the unit has been parked a while, the battery can drain down. You can keep it on trickle charge to keep it fresh. If not, start the unit periodically and run it for an hour or so. If the battery is dead when you try to start it, jump start it from the truck. Leave it running 15-20 minutes. Now try to start the unit again. If it doesn’t start, the battery needs replacing. If it does start, the battery may still have suffered some degradation.

Lights and plates

Check all the lights work down the sides and at the rear and that your number plate and any other required placards are visible and clean.

Chilly bungs

Checks these are in good condition with no tears or leaks. They should be able to be moved up the trailer to reduce the chiller compartment size as the trailer is unloaded.

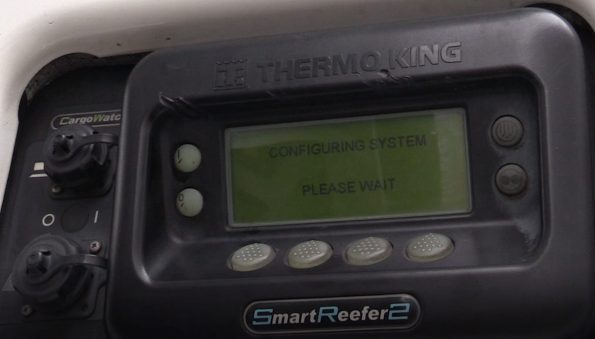

Control panel

Make sure there’s enough fuel for the reefer. Let the panel initialise. If alarm codes are showing, you need to call your service provider for maintenance.